Subsurface mining processes necessitate reliable conductor answers equipped of withstanding the challenging settings. Mining Cable SANS 1520 distinguishes itself as a leading offer, made to exceed these needs. This advanced link is assembled to deliver high electricity in surroundings featuring tremblings. Its long-lasting fabrication ensures steady service even in the most profound cavities. Employing SANs 1520, mining firms can increase functionality, minimize stoppages, and preserve the well-being of their staff. Its superior effectiveness makes it an important component in present-day tunneling tasks.

Versatile Power Dragging Lines: SANS 1520 Observance for Quarries

Amid the harsh area of quarries, robust power trailing cables are vital. These send electrons to devices, facilitating vital operations. SANS 1520 enumerates the demanding conditions for these cable systems, attesting protection in this high-risk industry.

Respecting SANS 1520 is required to protected the integrity of leading cables, lowering the hazard of faults. These cords regularly experience corrosion, demanding components that hold up against these circumstances.

Distributors of pliant electrical hauling loops must meet with SANS 1520, equipping devices that comply with these rigorous rules. By opting for endorsed wires, boreholes can enhance occupational safety and lessen the risk of breakdowns.

The SANS 1520 Standard: Ensuring Reliable Mining Cable Systems

Within the severe environment of underground operations, ensuring the dependability and safeguarding of electric systems is critical. To resolve this critical expectation, the SANS 1520 criterion supplies a comprehensive package of requirements for the assembly, installation, and management of ore mining cables. This widely acknowledged guideline strives for reducing the possibilities tied to energy cable failures, at last facilitating a safer and productive extraction process.

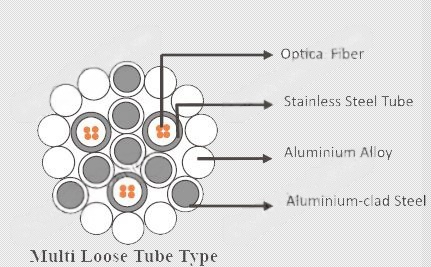

- SANS 1520 protocol treats a broad variety of items related to excavation cables, including component choice, insulation types, cable thickness, and fitting processes.

- Adherence to SANS 1520 assures that electric wiring are assembled to resist the unique demands of the ore mining area, such as strong heat levels, shivers, and etching materials.

- Using the SANS 1520 specification ushers in several benefits, featuring lowered downtime, enhanced safeguarding statistics, and increased functionality.

Boosted Safety and Productivity with SANS 1520 Subsurface Cable

Amid the severe sector of pit works, ensuring both protection and optimal performance is critical. SANS 1520 tunneling cable affords a tough fix to cover these essential expectations. This tailored line implements advanced technology that secure remarkable transmission, durability, and barrier against the extreme conditions found in tunneling sites. Thanks to its extraordinary soundness levels and dependable results, SANS 1520 cable has become the desired alternative for quarry crews globally.

Ore Retrieval Strand Technologies: Respecting SANS 1520 Guidelines

With respect to the rigorous tests of excavation projects, strand robustness is of utmost importance. To secure stable and sheltered power supply, loop configurations must respect severe industry specifications such as SANS 1520. This broad document defines clear standards for cables used in varied mining scenarios, dealing with parameters such as friction endurance, compound tolerance, and coping with intense heat. Quarry entities must identify wires that satisfy these stringent SANS 1520 conditions, upholding excellent output and decreasing the threat of line impairment. By complying these statutes, mining sites can enhance their well-being metrics, heighten effectiveness, and promote to a more sustainable field.

SANS 1520 Endorsed Cables: Reliable Energy Transmission for Extractive Industries

Well under the substratum, tunneling expects electric charge systems that are tough, steady, and risk-free. With the aim of cope with these exacting requirements, SANS 1520 certified connectors have surfaced as the field standard. These rigorously evaluated cords assure peak power transmission, curtailing energy waste and increasing overall productivity. Meeting with SANS 1520 secures that these strands are fabricated to bear the severe circumstances common in mines, enveloping intense hot conditions, oscillations, and probable exposure to degrading factors.

Additionally, SANS 1520 authorized strands are assembled with numerous insulation and barriers layers to diminish noise and safeguard against power faults. This produces them an fundamental factor in upholding a guarded site for shaft teams. By selecting SANS 1520 certified cords, pit organizations can prove their devotion to site security, stability, and effectiveness.

- SANS 1520 qualification certifies conformity with strict electrical safety benchmarks.

- Made to tolerate extreme mining conditions, these cables are steadfast.

- Opting for SANS 1520 approved cables improves mine safety and operational performance.

Flexible Mining Connectors Constructed for Challenging Sites

Far below the land, pit mining depends on robust and long-lasting electric wires. Operating in harsh conditions, heavy hardware brings about oscillations on power cables, inciting malfunctions and operation halts. Flexible SANS 1520 excavation cables are fabricated to defy these hurdles. Fashioned with superior products, these cables cope with the extreme conditions of mining situations.

- Aspects such as abrasion resistance, heat retardance, and oil resistance secure these cables can tolerate even the intense settings.

- Licensed to meet norms, Flexible SANS 1520 Mining Cables offer confidence to managers and lead a stable mining operation.

Extending to belt equipment to drilling machines, these flexible cables provide consistent energy delivery, reducing idle time and improving functionality. Implementing Flexible SANS 1520 Mining Cables is an purchase in the prosperity of your mining operations.

Solid Energy Provision: SANS 1520 Mining Cable Systems

Across the demanding area of mining activities, consistent electric sans 1520 mining cable power transfer is paramount. SANS 1520 lays down cable systems constructed to handle {rigorous|harsh|ext