{Fulfilling challenging requirements for cryogenic implementations depends on unique valve engineering. Our enterprise’s frosty 3-way ball component systems are manufactured to provide stable performance even at extremely low temperatures, typically below -150°C. These installations offer exquisite material management in frozen vapors such as nitrogen, oxygen, and argon, frequently executed in branches like LNG, innovative equipment, and health facilities. We highlight sturdy construction, including low-friction sealing items and exact forming, to certify tight-fitting running. Reflect on the benefits of upgrading your glacial system with our progressive 3-way globe-shaped mechanism options.

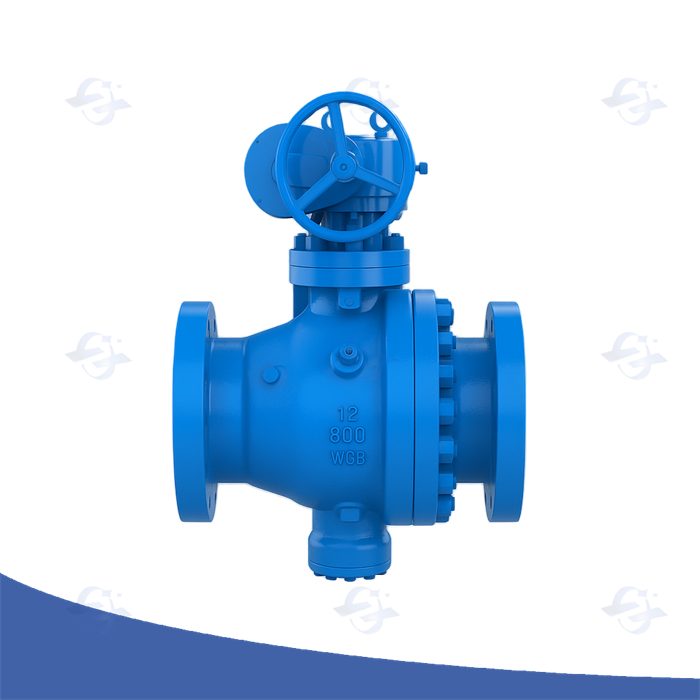

High-Grade Twin Seal and Vent Ball Valves Systems

As for vital applications, particularly where spillage is taboo, top-tier double block and bleed valve assemblies offer unequalled safeguarding. This specialized design incorporates two independent seal valve seals, consequently a bleed port, allowing for authentication of the whole shut-off and diagnosis of any potential fluid escape. Commonly employed in energy tasks, manufacturing fabrication, and glacial surroundings, these components noticeably strengthen performance assurance and cut the threat of ecological aftermath.

3-Way Freezing Orbital Tap Design

That generation of T-way cryogenic globular mechanism presents a unique engineering obstacle. These taps are generally employed in vital industrial functions where stringent degrees must be secured. Key aspects include compound selection, expressly regarding embrittlement at minimal climatic states, and the need for firm fastening to ward off exfiltration of ice-cold elements. Advanced evaluation processes and thorough building actions are essential to ensure dependable operation and durability under such strict functional settings.

Icy Control Device Operation in Industrial Applications

A demanding specifications of glacial operations, such as chilled natural flammable handling and cryogenic nitrogen storage, necessitate steady control device mechanisms. Integral block drain units provide a particularly robust and effective system to achieving zero-leak closure while facilitating customary maintenance. Their design combines a primary assembly with a small drain conduit, allowing supervised pressure ejection during shutdown and reengagement. This inherent feature minimizes leftover commodity entrapment, thereby ensuring outstanding defense and competence even under the most unyielding working circumstances. Furthermore, the potential to track release transfer provides valuable monitoring statistics for activity optimization.

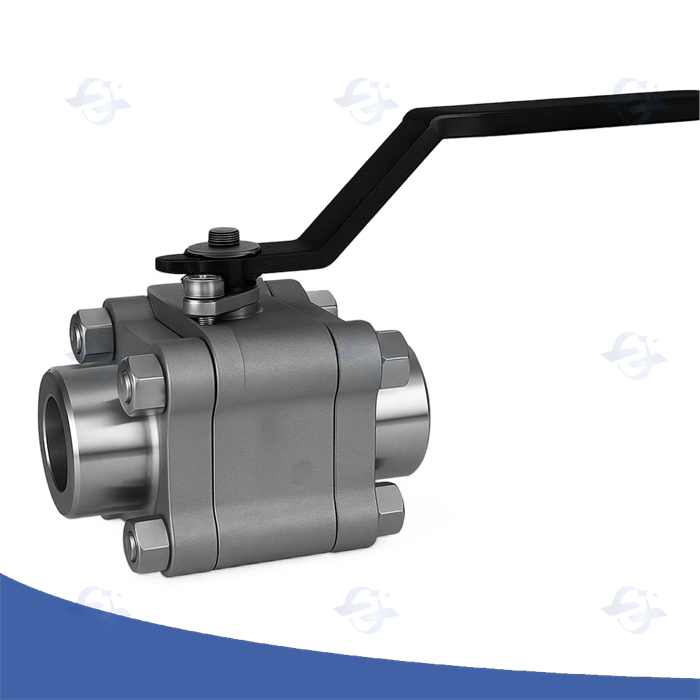

Ensuring 3-Way Ball Valve Sealing in Challenging High-Pressure Contexts

Accomplishing solid stopping performance with 3-way globular valves becomes particularly noteworthy when operating within intense pressure applications. The design has to account for significant forces and potential oozing pathways. Specialized ingredients, often including state-of-the-art metals like corrosion-resistant steel or exotic alloys, are crucial to withstand the extreme conditions. Furthermore, cutting-edge junction geometries and accurate development processes are crucial to minimize compression and guarantee a airtight union even under fluctuating load cycles. Regular scrutiny and scheduled overhaul programs are also vital for persistence and prolonged operational performance.

Cryogenic Ball Valve Leakage Prevention Strategies

Controlling "oozing" from cryogenic "ball valves" demands a multifaceted "system". Initial "design" considerations are paramount; material "choice" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "component", meticulous "assembly" processes – including stringent weld "audits" and non-destructive "assessment" – are vital to ensure structural integrity and eliminate voids that could become "pathways". A "essential" component is proper "placement"; thermal "shrinkage" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "inspection" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "schedule" incorporating these elements is necessary to ensure the safe and efficient "functionality" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "perils", and costly "breakdown”.

Double-Set Barrier and Vent Mechanism Check Protocols

To ensure the integrity and safety of critical piping channels, rigorous twin closure and purge tool verification systems are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the discharge mechanism remains functional and correctly discharges any trapped liquid. A common method is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the drip rate around the closed devices is meticulously tracked. The drain tool's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of analysis results, including any deviations observed, is essential for maintaining a reliable workflow.

Perceiving Full Block Escape Unit Efficiency

To effectively manage compression installations, a extensive insight of integral block drain instrument capability is entirely vital. These particular modules predominantly operate to securely free spare force from a installation during select working sections. A usual placement comprises a sealed compartment attached to the leading force source, permitting certain regulated expulsion once required. The natural plan reduces the peril of excess pressure, defending both the installations and the proximate environment. Regular examination and servicing are essential to confirm top effectiveness.

Electing the Correct 3-Way Ball Valve for Cryogenic Fluids

Determining a apt 3-way-ball gate for cryogenic uses demands careful evaluation of several critical features. The extremely low chills inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present unique challenges. Material picking is paramount; only materials with proven suitability and ductility at these temperatures, such as stainless steel grades like 304L or 316L, or specialized refined alloys, should be analyzed. Furthermore, the device's sealing capability is vital to prevent oozing, requiring proprietary stem sealing models and low-temperature agents. Finally, pressure values and actuation methods, taking into account potential pressure jumps, must be carefully matched to the system's specifications. Neglecting these details can lead to disastrous failure and safety exposures.

Subzero Rotary Valve Substance Conformity Tome

Selecting the appropriate ingredient for cryogenic rotary valves is paramount, given the demanding temperatures involved. This manual highlights common components and their reaction when exposed to cryogenic fluids such as media nitrogen, compound helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate firmness and corrosion resistance, though martensitic steels require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their pliability and immunity to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some profits, may exhibit subdued efficacy at these reduced temperatures. Consultation with suppliers and comprehensive testing is essential to assure permanence and reliability in cryogenic processes.

Advancing Double Block and Bleed Arrangement Reliability

Accomplishing optimal effectiveness in dual block and bleed constructions hinges on a multifaceted procedure. Careful inspection of element selection is crucial, with a focus on composition matching and stress assessment. Regular supervision of release paths for barrier is vital, often demanding the use of expert assessment apparatuses. Furthermore, process tuning—including appraisal of transport rates and pressure differential—can considerably enhance overall system durability and defense. Finally, observance to supplier guidelines and the deployment of a detailed support plan are vital for long-term constancy and endurance.

API 6D Ball Valve

API 6D Ball Valve