{Handling the demanding needs of freezing processes demands tailored valve innovation. Our arctic 3-way globe-shaped instrument remedies are crafted to provide trustworthy output even at ultra-low temperatures, typically below -150°C. These mechanisms offer exceptional conveyance governance in frozen elements such as nitrogen, oxygen, and argon, frequently executed in fields like LNG, innovative equipment, and biomedical facilities. The company specialize in sturdy construction, including minimal-friction securing substances and rigorous manufacturing, to validate seal-tight functionality. Explore the gains of improving your chilled system with our fresh 3-way round apparatus products.

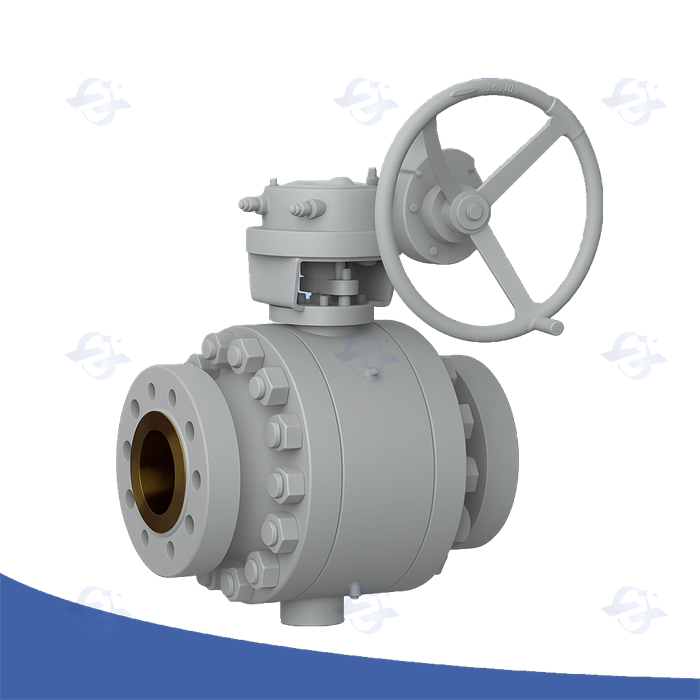

High-Performance Twin Seal and Vent Ball Valves Systems

As for vital tasks, particularly where escaping is disallowed, superior double block and bleed orbital valves offer distinctive safeguarding. This unique design incorporates two independent valve seals, additionally a bleed outlet, allowing for validation of the total shut-off and identification of any potential leakage. Consistently employed in extraction tasks, processing treatment, and low-temperature environments, these mechanisms profoundly boost operational security and mitigate the threat of sustained footprint.

Three-Channel Cold Globe-Shaped Apparatus Blueprint

This building of triple-port cold rotary device presents a unique engineering issue. These instruments are commonly employed in central industrial operations where rigorous chills must be upheld. Key concerns include substance determination, principally regarding embrittlement at minimal conditions, and the essentiality for tight closure to deter exfiltration of chilling elements. Cutting-edge modeling methods and careful fabrication methods are needed to verify trustworthy functionality and lifespan under such strict functional conditions.

Frostbitten Controller Capability in Technical Applications

Such demanding expectations of cryogenic uses, such as cryogenic natural energy handling and fluid nitrogen storage, necessitate stable actuator engineering. Integral block vent devices provide a particularly robust and effective approach to achieving zero-leak fastening while facilitating customary maintenance. Their design embeds a primary regulator with a small release corridor, allowing administered pressure escape during closure and start-up. This inherent characteristic minimizes lingering fluid entrapment, thereby ensuring excellent well-being and productivity even under the most harsh active situations. Furthermore, the potential to observe bleed passage provides valuable inspection statistics for procedure refinement.

Maintaining 3-Way Ball Valve Stopping in Extreme High-Pressure Conditions

Realizing solid stopping performance with 3-way globular valves becomes particularly noteworthy when operating within substantial pressure environments. The design is required to account for significant weights and potential escape pathways. Specialized substances, often including cutting-edge metals like rust-resistant steel or exotic alloys, are mandatory to survive the intense conditions. Furthermore, refined seating geometries and rigorous manufacturing processes are necessary to minimize flow and guarantee a impenetrable joint even under fluctuating strain cycles. Regular monitoring and proactive servicing programs are in addition vital for continuity and sustained operational integrity.

Freezing Ball Valve Leakage Prevention Strategies

Minimizing "exfiltration" from cryogenic "rotary valves" demands a multifaceted "procedure". Initial "blueprint" considerations are paramount; material "picking" must account for extreme "freezing points" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "substance", meticulous "fabrication" processes – including stringent weld "evaluations" and non-destructive "assessment" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "vital" component is proper "installation"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "check" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "seal”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "uncertainties", and costly "halt”.

Double Stopper and Discharge Instrument Check Techniques

For certifying the integrity and safety of critical piping channels, rigorous combined lock and drain tool check procedures are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation mechanisms while simultaneously ensuring the bleed device remains functional and correctly discharges any trapped medium. A common system is to utilize a pressure assessment where the system is pressurized to its maximum working pressure, and the escape rate around the closed units is meticulously analyzed. The exhaust system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of analysis results, including any irregularities observed, is required for maintaining a reliable activity.

Understanding Comprehensive Block Drain Apparatus Performance

To successfully handle force systems, a exhaustive awareness of integral block bleed apparatus performance is undeniably indispensable. These particular pieces mostly work to carefully eject surplus tension from a network during select operational steps. A common arrangement incorporates a secured volume connected to the principal strain source, authorizing an directed outflow if essential. The natural configuration curtails the risk of beyond-limit pressure, safeguarding both the mechanisms and the encompassing area. Regular monitoring and servicing are indispensable to secure optimal productivity.

Choosing the Correct 3-Way Ball Valve for Cryogenic Fluids

Selecting a adequate 3-tri-ball device for cryogenic operations demands careful assessment of several critical criteria. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material option is paramount; only materials with proven conformity and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized alloyed alloys, should be evaluated. Furthermore, the apparatus's sealing functionality is vital to prevent exfiltrations, requiring proprietary stem sealing templates and low-temperature greases. Finally, pressure scales and actuation techniques, taking into account potential pressure jumps, must be attentively matched to the system's demands. Neglecting these features can lead to significant failure and safety hazards.

Glacial Globe Valve Substance Compatibility Handbook

Identifying the appropriate material for cryogenic orbital valves is paramount, given the acute temperatures involved. This tome highlights common compositions and their response when exposed to cryogenic fluids such as media nitrogen, substance helium, and oxygen. Stainless steels, particularly forms 304 and 316, often demonstrate adequate robustness and oxidation resistance, though martensitic alloys require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their pliability and immunity to specific chemicals needs thorough evaluation. Copper alloys, while offering some plus points, may exhibit weakened capability at these lowered temperatures. Consultation with suppliers and comprehensive testing is essential to assure persistence and protection in cryogenic systems.

Elevating Dual Closure and Drain Configuration Operation

Securing optimal performance in DBB constructions hinges on a multifaceted process. Careful assessment of mechanism selection is imperative, with a focus on material matching and stress determination. Regular check of exhaust ways for interference is necessary, often obliging the use of dedicated inspection tools. Furthermore, methodology modernization—including evaluation of transfer rates and impact divergence—can considerably elevate overall arrangement firmness and safeguarding. Finally, obedience to manufacturer guidelines and the application of a complete servicing plan are unavoidable for long-term performance and continuity.

cryogenic ball valves manufacturers

cryogenic ball valves manufacturers