g

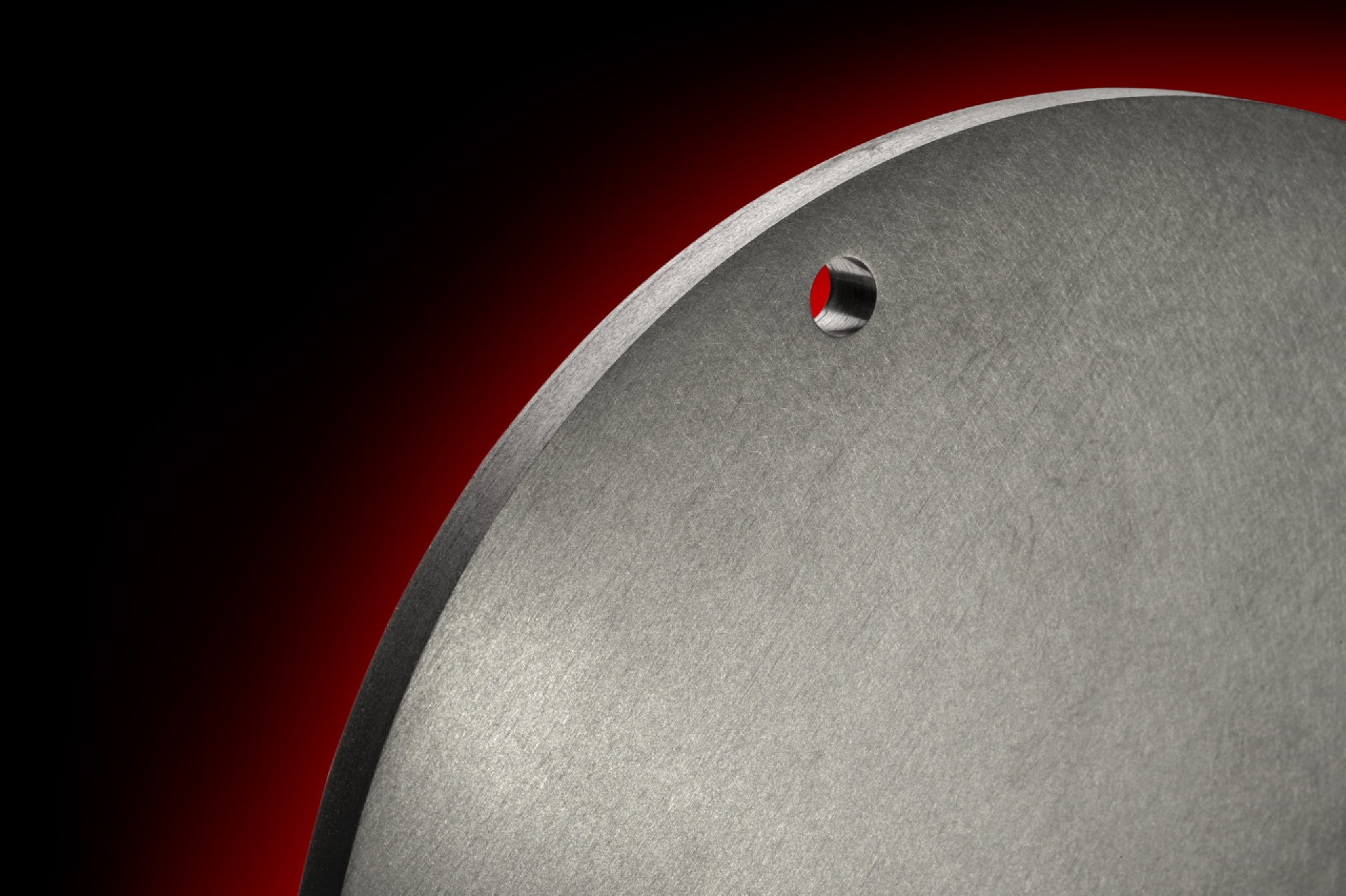

Titanium-6Al-4V, usually named as Titanium 6-4, characterizes a distinctly extraordinary feat in engineering materials. Its ingredients – 6% aluminum, 4% vanadium, and the remaining balance made up of titanium – provides a union of traits that are complex to imitate in various load-bearing substance. Pertaining to the aerospace sector to healthcare implants, and even top-tier automotive parts, Ti6Al4V’s notable sturdiness, errosion defense, and relatively manageable character allow it certain incredibly multifunctional choice. Notwithstanding its higher expenditure, the effectiveness benefits often authenticate the commitment. It's a testament to what carefully guided formulating process is able to truly create an distinctive outcome.

Exploring Stuff Features of Ti6Al4V

Titanium 6Al4V, also known as Grade 5 titanium, presents a fascinating fusion of mechanical features that make it invaluable across aerospace, medical, and production applications. Its designation refers to its composition: approximately 6% aluminum, 4% vanadium, and the remaining percentage titanium. This specific integration results in a remarkably high strength-to-weight proportion, significantly exceeding that of pure titanium while maintaining excellent corrosion endurance. Furthermore, Ti6Al4V exhibits a relatively high stretchiness modulus, contributing to its spring-like behavior and convenience for components experiencing repeated stress. However, it’s crucial to acknowledge its lower ductility and higher payment compared to some alternative constituents. Understanding these nuanced properties is essential for engineers and designers selecting the optimal response for their particular needs.

6Al-4V Titanium : A Comprehensive Guide

Titanium alloy 6-4, or Ti64, represents a cornerstone constituent in numerous industries, celebrated for its exceptional poise of strength and moderate properties. This alloy, a fascinating amalgamation of titanium with 6% aluminum and 4% vanadium, offers an impressive weight-to-strength ratio, surpassing even many high-performance alloys. Its remarkable deterioration resistance, coupled with superb fatigue endurance, makes it a prized choice for aerospace functions, particularly in aircraft structures and engine sections. Beyond aviation, 6Al-4V finds a niche in medical implants—like hip and knee fixtures—due to its biocompatibility and resistance to body fluids. Understanding the blend's unique characteristics, including its susceptibility to particle embrittlement and appropriate thermal treatment treatments, is vital for ensuring physical integrity in demanding conditions. Its fabrication can involve various procedures such as forging, machining, and additive manufacturing, each impacting the final attributes of the resulting good.

Titanium 6Al4V Blend : Composition and Characteristics

The remarkably versatile composition Ti 6 Al 4 V, a ubiquitous hard metal composition, derives its name from its compositional makeup – 6% Aluminum, 4% Vanadium, and the remaining percentage element. This particular coalescence results in a component boasting an exceptional integration of properties. Specifically, it presents a high strength-to-weight relationship, excellent corrosion longevity, and favorable heat characteristics. The addition of aluminum and vanadium contributes to a robust beta level design, improving flexibility compared to pure element. Furthermore, this blend exhibits good connection potential and processability, making it amenable to a wide range of manufacturing processes.

Titanium 6Al4V Strength and Performance Data

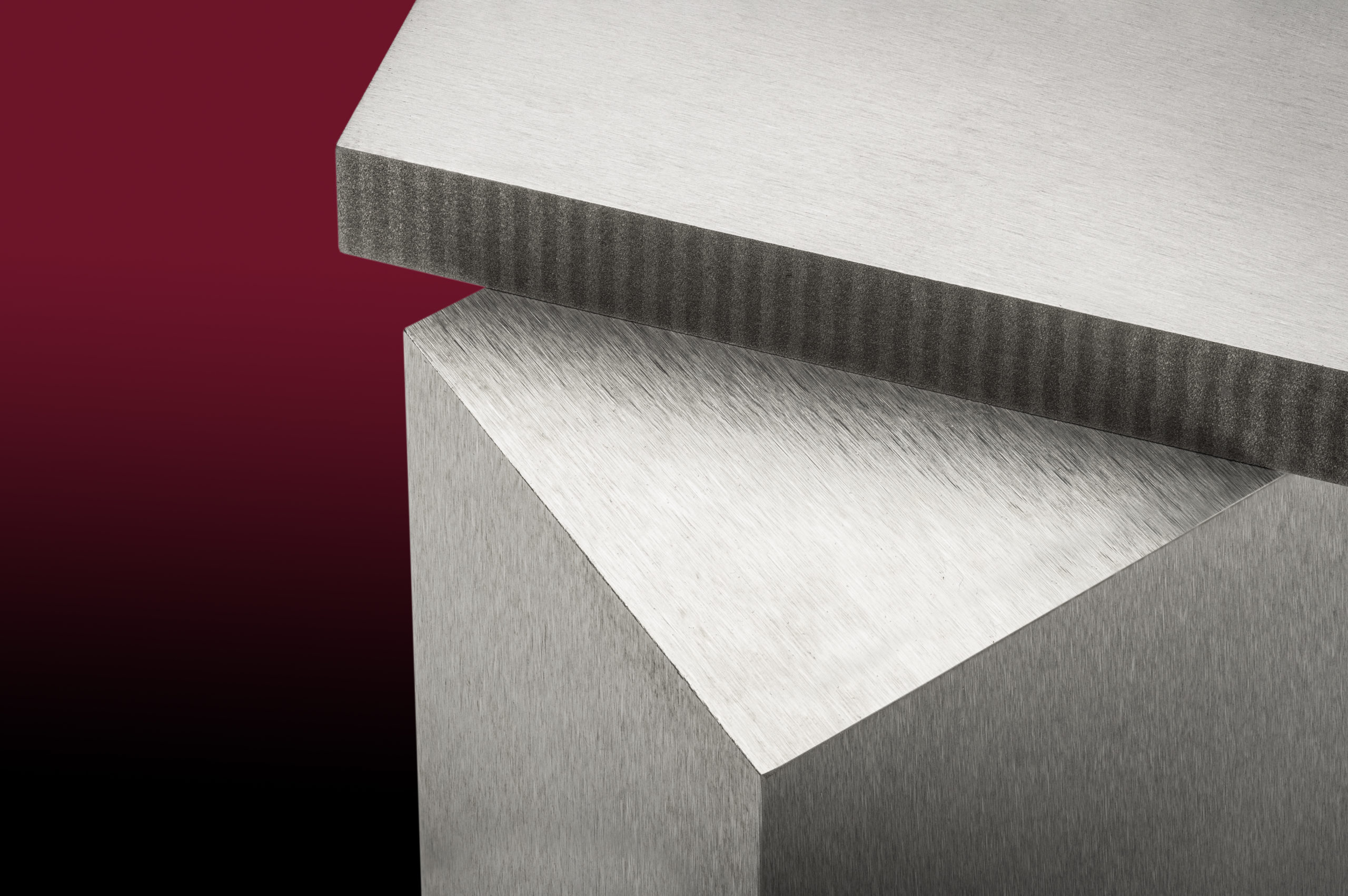

The remarkable amalgamation of toughness and chemical durability makes Ti6Al4V a widely adopted material in aerospace engineering engineering, healthcare implants, and high-performance applications. Its ultimate tensile strength typically spans between 895 and 950 MPa, with a stretch limit generally between 825 and 860 MPa, depending on the particular heat treatment approach applied. Furthermore, the compound's mass density is approximately 4.429 g/cm³, offering a significantly positive weight-to-strength ratio compared to many traditional carbon steels. The elastic modulus, which indicates its stiffness, is around 113.6 GPa. These traits lead to its far-reaching approval in environments demanding as well as high mechanical reliability and sturdiness.

Mechanical Properties of Ti6Al4V Titanium

Ti6Al4V alloy, a ubiquitous Ti alloy in aerospace and biomedical applications, exhibits a compelling suite of mechanical specifications. Its extension strength, approximately 895 MPa, coupled with a yield robustness of around 825 MPa, signifies its capability to withstand substantial stresses before permanent deformation. The extension, typically in the range of 10-15%, indicates a degree of pliability allowing for some plastic deformation before fracture. However, crumbly quality can be a concern, especially at lower temperatures. Young's modulus, measuring about 114 GPa, reflects its resistance to elastic bending under stress, contributing to its stability in dynamic environments. Furthermore, fatigue durability, a critical factor in components subject to cyclic loading, is generally good but influenced by surface quality and residual stresses. Ultimately, the specific mechanical response depends strongly on factors such as processing approaches, heat conditioning, and the presence of any microstructural inconsistencies.

Electing Ti6Al4V: Implementations and Advantages

Ti6Al4V, a commonly used titanium substance, offers a remarkable fusion of strength, wear resistance, and animal compatibility, leading to its far-reaching usage across various sectors. Its slightly high price is frequently justified by its performance characteristics. For example, in the aerospace business, it’s fundamental for developing aircraft components, offering a remarkable strength-to-weight ratio compared to traditional materials. Within the medical discipline, its intrinsic biocompatibility makes it ideal for therapeutic implants like hip and leg replacements, ensuring longevity and minimizing the risk of repudiation. Beyond these principal areas, its also utilized in motor racing parts, competitive items, and even user products requiring high performance. Eventually, Ti6Al4V's unique traits render it a noteworthy fabric for applications where trade-off is not an option.

Appraisal of Ti6Al4V In relation to Other Ti-based Alloys Alloys

While Ti6Al4V, a renowned alloy boasting excellent hardness and a favorable strength-to-weight scale, remains a leading choice in many aerospace and biomedical applications, it's vital to acknowledge its limitations opposed to other titanium compositions. For sample, beta-titanium alloys, such as Ti-13V-11Fe, offer even amplified ductility and formability, making them ideal for complex manufacturing processes. Alpha-beta alloys like Ti-29Nb, demonstrate improved creep resistance at heightened temperatures, critical for combustion components. Furthermore, some titanium alloys, manufactured with specific alloying elements, excel in corrosion protection in harsh environments—a characteristic where Ti6Al4V, while good, isn’t always the foremost selection. The option of the proper titanium alloy thus is contingent upon the specific expectations of the recommended application.

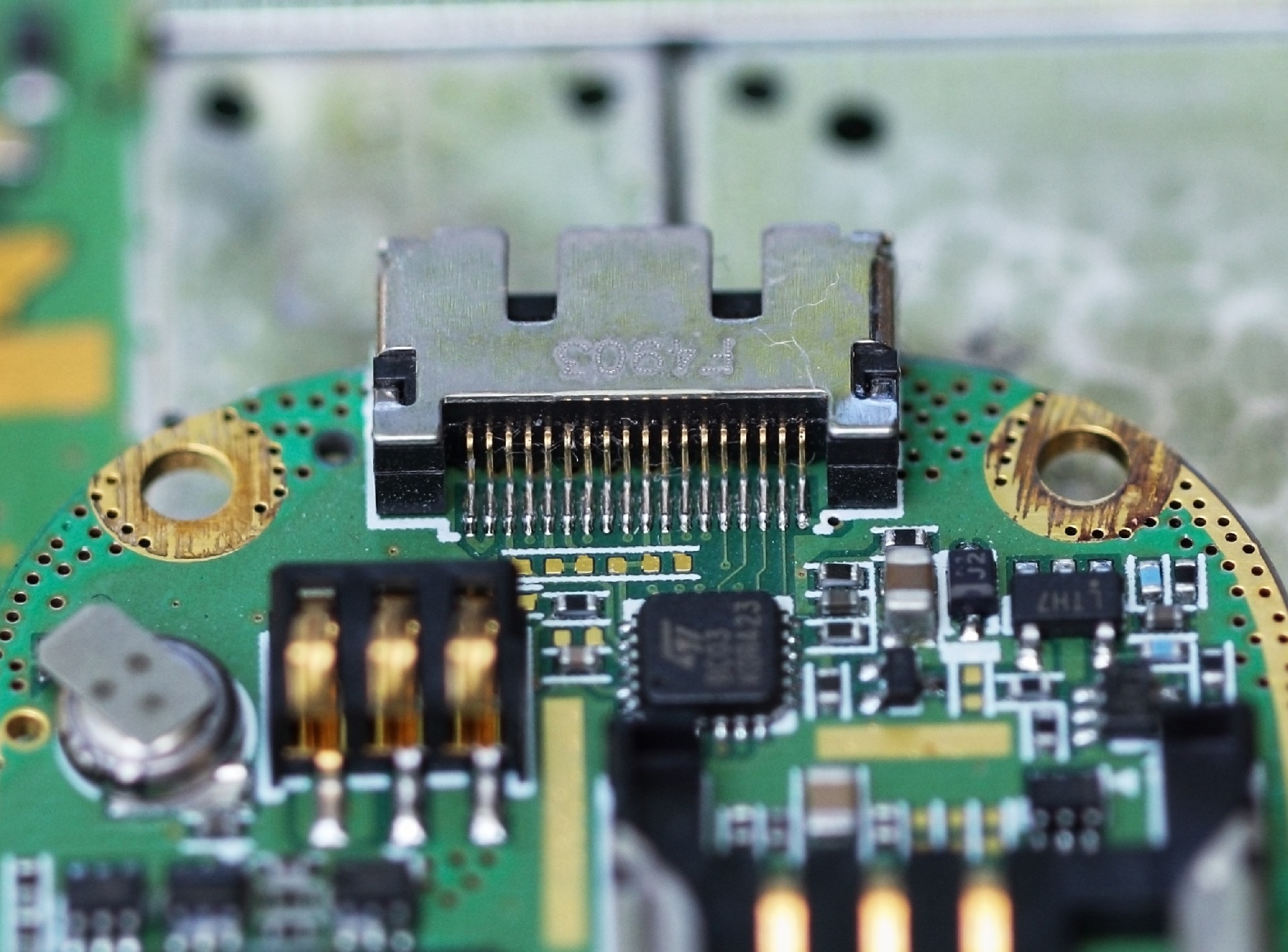

Titanium 6-4: Processing and Manufacturing

The assembly of components from 6Al-4V element necessitates careful consideration of various processing approaches. Initial piece preparation often involves vacuum melting, followed by hot forging or rolling to reduce width dimensions. Subsequent machining operations, frequently using plasma discharge processing (EDM) or robotic control (CNC) processes, are crucial to achieve the desired final geometries. Powder Metallurgy (PM|Metal Injection Molding MIM|Additive Manufacturing) is increasingly utilized for complex outlines, though compactness control remains a major challenge. Surface layers like anodizing or plasma spraying are often implemented to improve corrosion resistance and tear properties, especially in rigorous environments. Careful annealing control during annealing is vital to manage stress and maintain elasticity within the assembled part.

Degradation Fortitude of Ti6Al4V Element

Ti6Al4V, a widely used substance fabric, generally exhibits excellent fortitude to corrosion in many environments. Its shielding in oxidizing backgrounds, forming a tightly adhering layer that hinders subsequent attack, is a key parameter. However, its manifestation is not uniformly positive; susceptibility to pit impairment can arise in the presence of chemical species, especially at elevated temperatures. Furthermore, galvanic coupling with other substances can induce degradation. Specific purposes might necessitate careful analysis of the fluid and the incorporation of additional buffering practices like sealants to guarantee long-term endurance.

Ti6Al4V: A Deep Dive into Aerospace Material

Ti6Al4V, formally designated Ti 6-4-V, represents a cornerstone element in modern aerospace engineering. Its popularity isn't coincidental; it’s a carefully engineered mixture boasting an exceptionally high strength-to-weight ratio, crucial for minimizing structural mass in aircraft and spacecraft. The numbers "6" and "4" within the name indicate the approximate amounts of aluminum and vanadium, respectively, while the "6" also alludes to the approximate percentage of titanium. Achieving this impressive performance requires a meticulously controlled formation process, often involving vacuum melting and forging to ensure uniform structure. Beyond its inherent strength, Ti6Al4V displays excellent corrosion withstanding ability, further enhancing its endurance in demanding environments, especially when compared to options like steel. The relatively high cost often necessitates careful application and design optimization, ensuring its benefits outweigh the financial considerations for particular purposes. Further research explores various treatments and surface modifications to improve fatigue aspects and enhance performance in extremely specialized cases.

c-103 rod

c-103 rod